- Home

- Automate with AI

- Mitsubishi Electric

24/7 monitoring of critical facilities

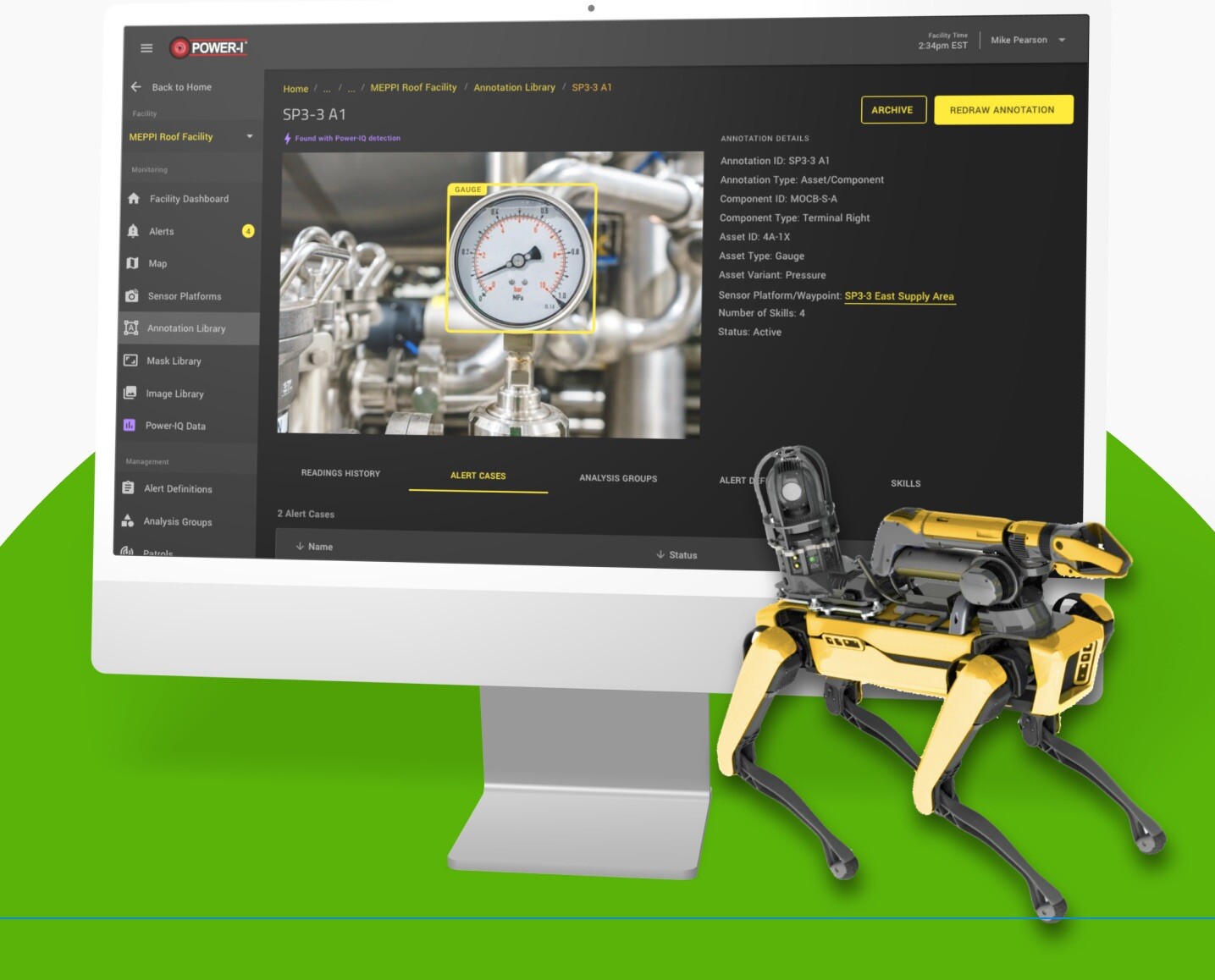

Mitsubishi Electric — a global leader in electrical products and systems — is innovating solutions for power substation managers to keep critical infrastructure equipment operational and avoid unplanned outages. The Power-I platform applies AI to autonomously gather, detect, and report anomalous issues of concern in the data being gathered by fixed cameras and mobile robotic sensor platforms.

At-a-Glance

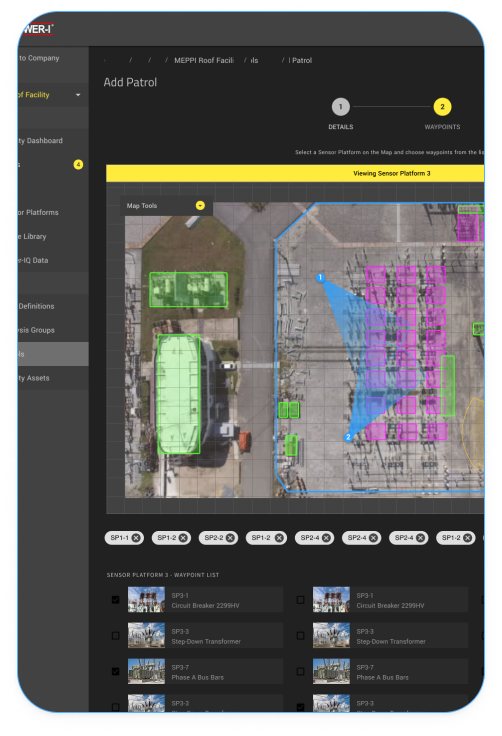

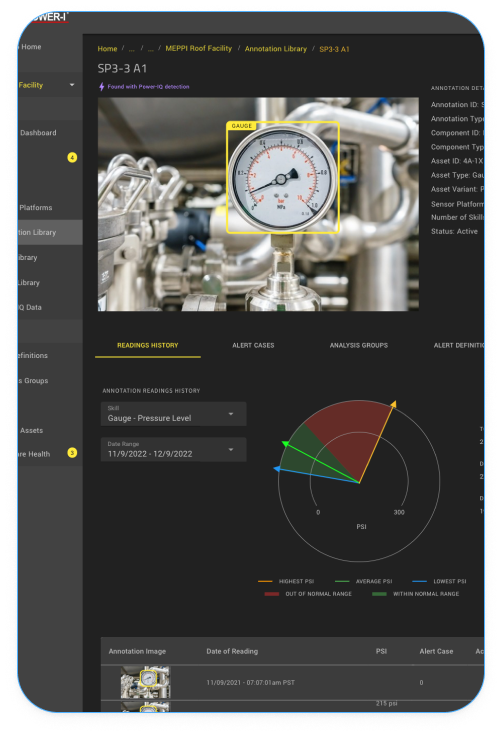

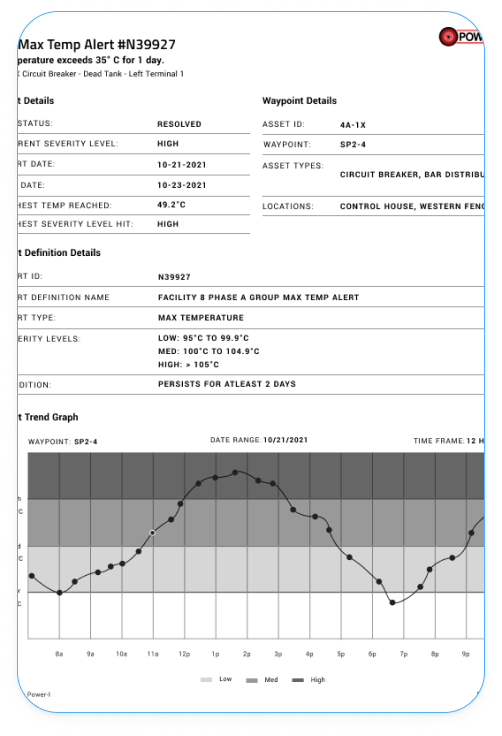

Truefit worked with Mitsubishi to understand and address many complex aspects of remote control for cameras and robots. We applied computer vision and AI solutions to automate image processing and data analysis to inform early warning systems and reporting for critical infrastructure assets. The Power-I platform informs site managers about anomalous readings outside of normal ranges and changing conditions at the substation for improved resiliency and protection.

Delivering customer value that creates business impact

Desired business outcomes- Demonstrably improve safety and risk for unplanned outages at substations

- Expand in-house expertise with software, AI, and robotics development to complement their leadership in hardware solutions

- Leverage their data to enable unique AI-driven solutions

- Establish sales and “best-in-class” market position

- Decrease O&M expenses by reducing onsite inspections

- Improve proactive response to events and equipment problems

- Reduce frequency and duration of unplanned service outages

- Enable more productive, cost-effective use of personnel

- Improve employee safety by reducing exposure to danger

- Protect equipment and extend lifespan

- Software that is easy to set up, learn, and use

Testimonial from client. — Mike Doak, Product Manager

Product Details

How we did it

Kickoff

We learned about their product vision, domain expertise, hardware capabilities, and tech requirements.

Understand user needs

Getting access to users during the pandemic was a major barrier at first. However, we were able to work with industry experts early on and surveys to start to inform our understanding. An advisory board of industry experts proved to be very helpful for early operational perspective.

Market research

We closely studied competing offerings, other technical approaches, and emerging industry trends

Technical R&D

We tackled numerous early challenges for camera selection and integration, automated data analysis, weather data integration, image storage, and informing machine learning algorithms.

Design foundations and prototyping

We collaborated as a team to define early information architecture and concepts, content models, and key workflows for each feature. As design patterns started to emerge we explored visual UI style options. The use of iterative design prototypes helped us to attract professionals willing to engage in early design research.

System architecture

We defined structures and schemas that would support the complex workflows and storage needs of the submission process.

Release planning

We collaborated with our client to build a roadmap based on our learnings and planned a series of iterative releases of the feature sets that we could test onsite.

Build, build, build!

We designed, coded, and tested on a weekly basis releasing multiple iterations of the platform — first with fixed pan & tilt cameras and later with the Spot robot.

Transition to their in-house team

Truefit helped MEPPI to hire and train their first internal software team and bring the project in-house to manage the day-to-day details of the program.

Prepare for early market tests

The platform elements are now moving into early market testing for a solution involving both the thermal imaging cameras and the Spot robot with some of the nation’s leading power utilities.

Refinements and future enhancements

Once the app was complete and in the hands of real users, we continued to work with our client to enhance the experience where needed. Despite how it may seem, software is never done!