- Home

- Improve robot ux

- HEBI Robotics

Test-driving virtual robots for research

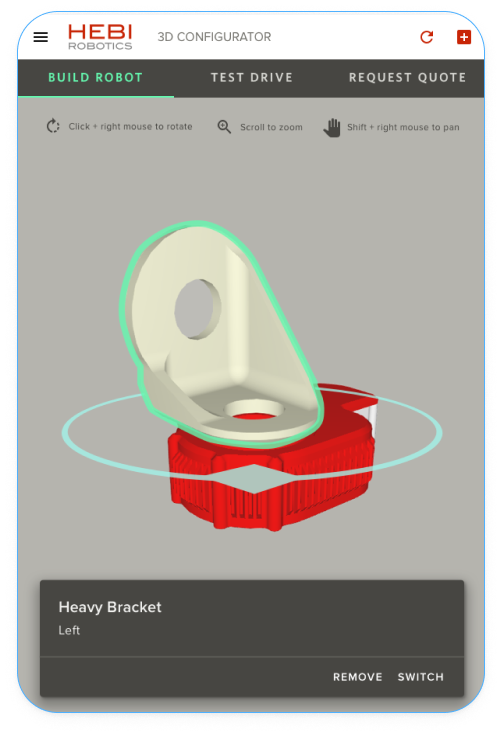

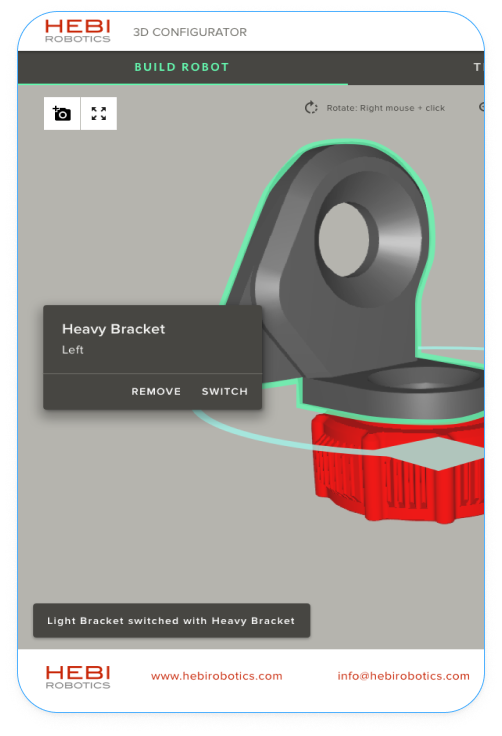

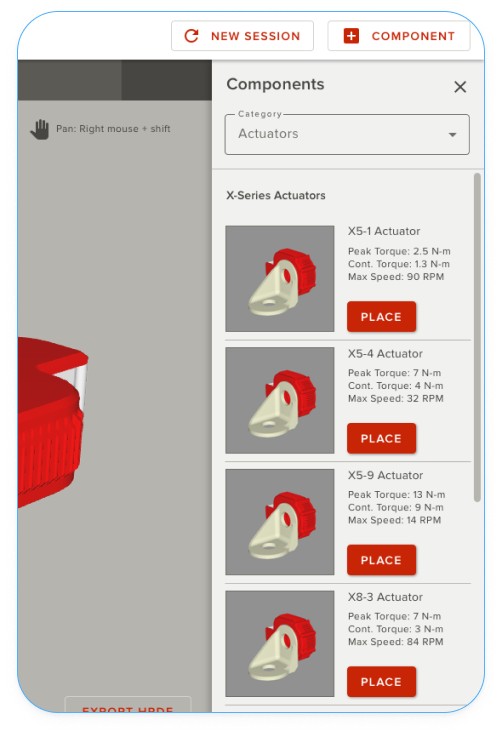

HEBI Robotics — an innovative provider of robotic actuators and components — needed to simulate the physical properties of their systems for researchers in a virtual environment. Using Web GL and reverse kinematics, could Truefit build an online tool to let researchers test-drive and configure their robot before purchase?

At-a-Glance

Before we could tackle a product solution, Truefit first needed to prove the feasibility of assembling 3D elements from HEBI’s CAD files in a web browser and accurately calculating maximum payloads at various positions. From there, Truefit was able to design and build an engaging solution for building virtual robots and running accurate simulations before submitting a request for a quote.

Delivering customer value that creates business impact

Desired business outcomes- Increase sales

- Improve customer confidence prior to quoting

- Improve understanding of customers’ robotics applications

- Reinforce brand persona as innovator, customer-focused

- Fun and easy-to-compare alternate solution

- Confidence in the physical capabilities of the design

- Convenient introduction to a discussion with sales

Headline

Attracted new clients

Increased search volume

Reduced time to discover relevant patents

Attracted follow on funding?

Impacts to date

Generated positive word of mouth and feedback from customers

Proven to be a useful internal tool for their sales team to run quick design and calculate capabilities

“Truefit did a great job of setting the stage for our project, managing the project and guiding us through the process of creating our robot configurator from beginning to end - essentially becoming an extension of the HEBI team. Truefit is a very technically capable and well organized partner” — Bob Raida, CEO

Product Details

How we did it

Kickoff

We learned about our clients product vision, strategy, and business model.

Initial proof of concept

Our engineers built a working proof of concept confirming the feasibility of snap-drag 3D modeling in the browser and the accuracy of kinematics simulation.

Early design exploration

Having proven feasibility, the team went to work to sketch out early workflows for assembling robots from an online parts catalog and testing them online. We also focused on visual style and brand considerations.

Release planning

We collaborated with our client to define what must be present in the initial release in terms of foundations, core requirements, and feature functionality.

Software architecture and strategy

Our architect and engineers resolved complexities around uploading and storing CAD models and rendering in the browser interface, building the online catalog of 3D models and customizing each part for simulation.

Connecting to sales workflow

The engineers wrote code to extract the parts list from the customers’ designs and format it for submission to the sales team. The customer’s contact information and notes could be sent to a sales associate for quoting.

Build, build, build!

We designed, coded, and tested on a weekly basis until we were feature complete for the first release. Progress was demoed on a bi-weekly basis.

Prepare for launch

Once the app was complete and QA tested, we assisted our client in deploying the app on their servers so they could take over maintenance at that point.

Release planning

We collaborated with our client to build a backlog and plan the build of the software in a way that met the key milestones needed to get to market.

Build, build, build!

We designed, coded, and tested on a weekly basis until we were feature complete for the first release.

Prepare for launch

Once the app was complete and fully QA tested, we assisted our client in deploying the software on their production servers. The launch was a success and we helped transition their code and all production assets to their internal team.